Why Winter Puts Extra Strain on Reefer Units (and How to Prevent Breakdowns)

For fleet managers in New England and across the Northeast, winter brings more than snow and icy roads. It also puts refrigerated trailers and trucks under unique stress.

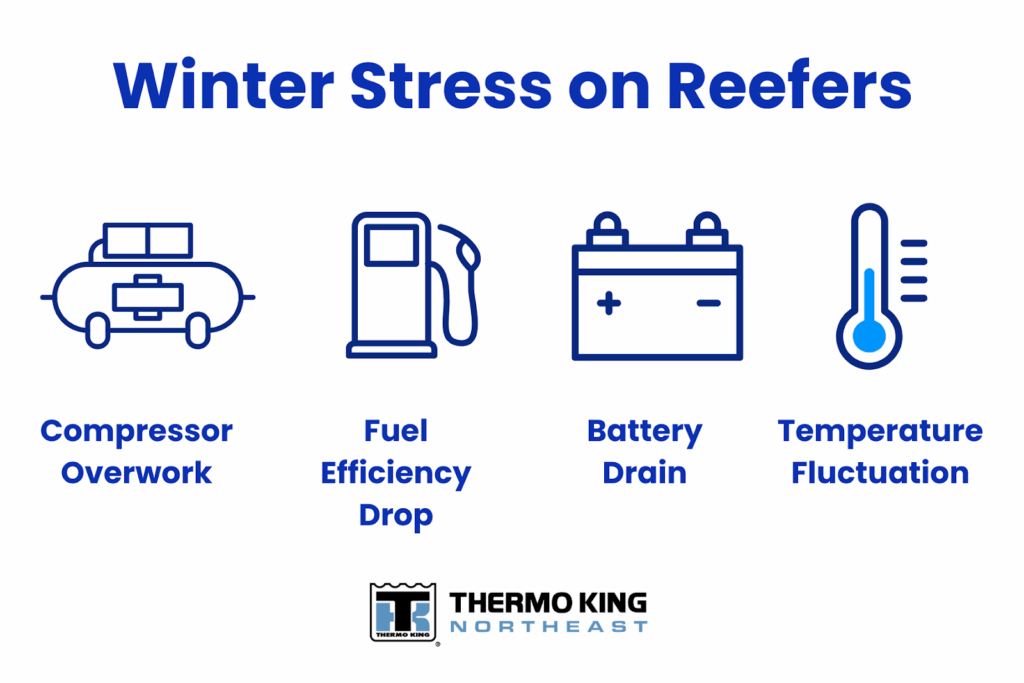

In cold weather, engines and refrigeration systems lose efficiency. Studies show fuel economy can drop 10–20%, and diesel engines are up to five times harder to start in extreme cold. Combine that with reduced battery power and you’ve got a recipe for breakdowns.

Why Winter Strains Reefer Units

1. Frequent Temperature Fluctuations

Cold air outside doesn’t always make cooling easier. In fact, drastic shifts between freezing outdoor temps and insulated cargo space can cause reefer units to cycle more often. This creates added wear on compressors and increases fuel consumption.

2. Overcooling and Product Risk

When temperatures outside drop well below freezing, reefers risk “overcooling.” Products like fresh produce, beverages, and pharmaceuticals may require cool, not frozen, environments. Without careful monitoring, winter conditions can push units to drop below safe thresholds, putting sensitive cargo at risk.

3. Increased Fuel Consumption

While summer heat drives units to work harder, winter isn’t fuel-efficient either. Diesel engines powering reefers run less efficiently in extreme cold, and longer warm-up times add to consumption. Combine this with frequent cycling, and winter fuel use can climb significantly.

4. Wear and Tear from Road Salt & Ice

In addition to accelerating corrosion on truck bodies and frames, snow, slush, and road salt also accelerates corrosion on reefer components. Salt buildup on condenser coils, wiring, and undercarriage parts can shorten equipment lifespan if not properly cleaned and maintained.

How to Prevent Winter Breakdowns

Stay on Top of Maintenance

- Check door seals and insulation: Even small air leaks force units to work overtime.

- Service compressors and belts: Cold weather increases stress on mechanical parts.

- Clean condenser coils: Salt and grime buildup reduces efficiency.

- Schedule your pre-winter reefer service with our certified Thermo King technicians.

Monitor Temperatures Closely

Modern reefers are equipped with intelligent temperature controls and remote monitoring. Use these systems to prevent overcooling and catch fluctuations before they damage cargo.

Winterize Your Fleet

- Use winter-grade fuel and additives to prevent gelling.

- Inspect electrical connections and battery health, cold drains power faster.

- Wash equipment regularly to remove road salt and prevent corrosion.

Train Your Drivers

Ensure your drivers know how to spot temperature irregularities, manage unit defrost cycles, and report issues before they become costly failures.

Protect Your Fleet This Winter

The cold months don’t have to mean higher operating costs and risk. With proactive maintenance, smart monitoring, and proper winterization, you can protect both your cargo and your equipment investment.

At Thermo King Northeast, our service experts are here to help you prepare your fleet for winter conditions. From preventive maintenance to emergency repairs, we’ll make sure your reefers keep running, no matter how cold it gets.

FAQ

Q: Do reefer units work harder in cold weather?

A: Yes. In cold weather, reefer units cycle more frequently to maintain consistent temperatures, prevent overcooling, and protect perishable cargo. Components like compressors and sensors must work harder to stabilize internal temperatures.

Q: Why do reefer units burn more fuel in winter?

A: Cold weather affects both the engine and refrigeration system. Fuel thickens, engines take longer to warm up, and reefers may run longer cycles to prevent freezing—all of which increase fuel use.

Q: How can I prepare my reefer units for winter?

A: Inspect insulation and door seals, service compressors and belts, winterize fuel and batteries, and verify your temperature control systems are calibrated correctly. Regular preventive maintenance is the best defense against winter breakdowns.

Q: Can cold weather damage refrigerated cargo?

A: Yes. Sensitive cargo like produce, dairy, or pharmaceuticals can freeze if temperatures drop below set points. Using calibrated sensors and monitoring systems ensures products stay within safe ranges.