As January comes to a close, refrigeration fleets servicing produce, dairy, meat, and frozen goods begin preparing for one of the busiest periods of the year. Getting your transport refrigeration units checked, repaired, and updated before the spring harvest and summer heat is critical to protecting cargo, reducing breakdowns, and controlling costs.

Thermo King fleet maintenance programs have long highlighted the value of proactive care. Customers using proactive vs reactive maintenance sees up to 18% cost savings, and service contracts can lead to as much as 39% fewer on-road repairs. In one case, unscheduled events dropped by 82% after maintenance plans were adopted.

Why the Beginning of the Year is the Ideal Time for Maintenance

Winter’s slower traffic provides the perfect window to bring units into the shop without disrupting your hauling schedule too much. Key reasons why January and February matter:

- Low season for hauls gives technicians more availability.

- Winter wear and tear becomes obvious when systems return from cold service. Cold weather stresses belts, seals and electrical systems. Catching issues early prevents failures under heat stress later.

- Manufacturers like Thermo King recommend regular service in cooler months before ambient heat increases work load on systems.

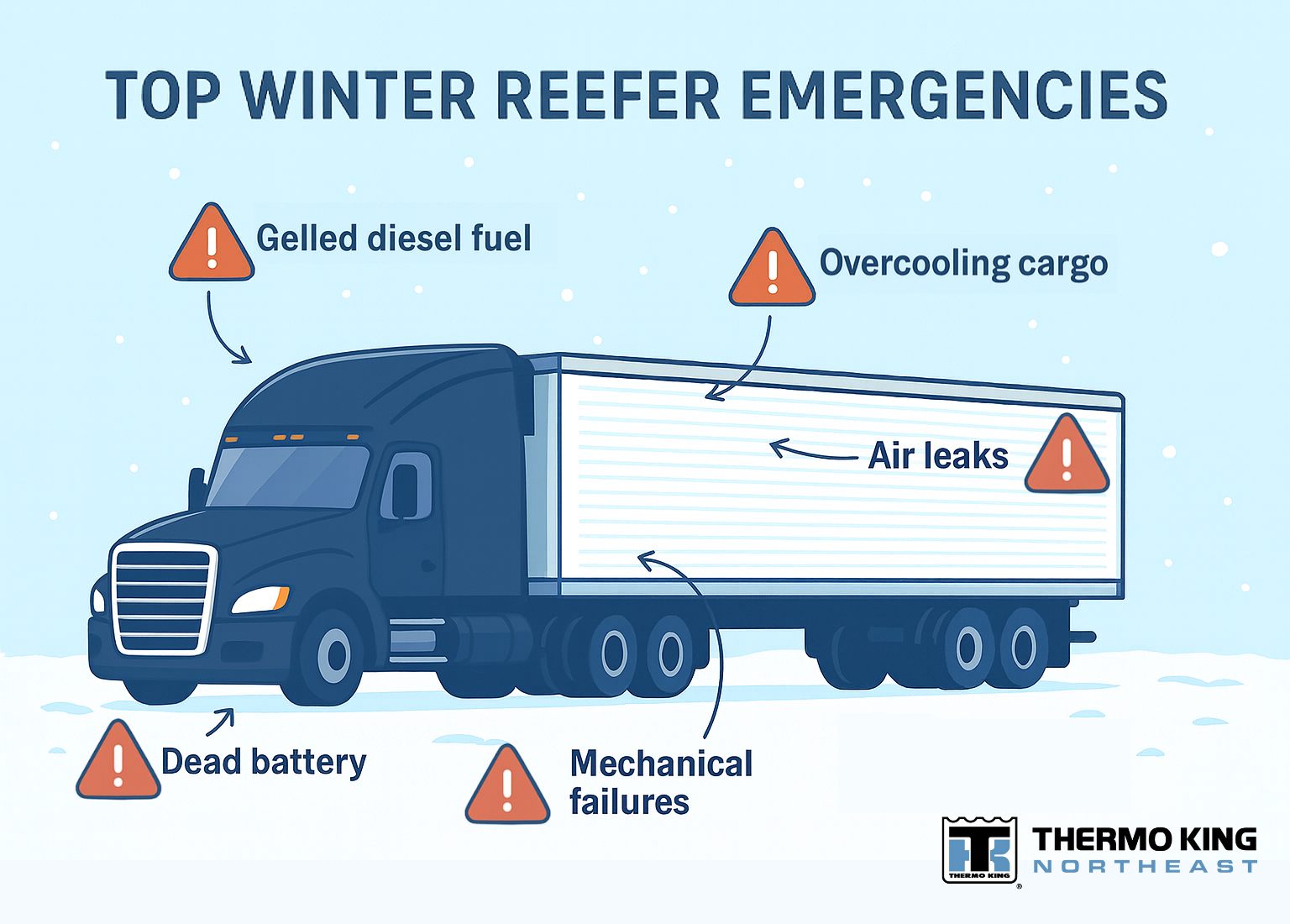

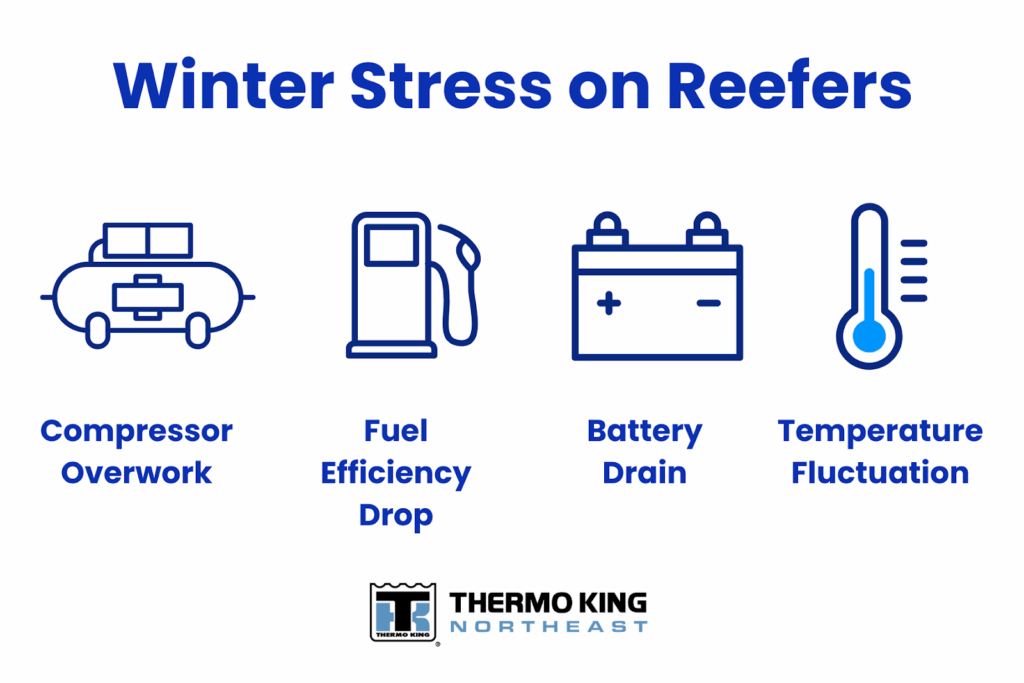

Common Winter Issues Affecting Refrigeration Performance

Even when units aren’t hauling, winter conditions can cause hidden damage:

- Condensation and corrosion on electrical components.

- Cold-weather stress on belts, hoses, and gaskets that may harden or crack.

- Battery drain and fuel gelling that affects unit starts and diagnostics.

Addressing these now means fewer surprises when temperatures rise. Read more about winter weather issues.

Pre-Season Inspection Checklist for Truck and Trailer Units

Here’s a practical checklist experienced fleet managers use before the peak season:

Mechanical & Fluid Checks

- Belt tension and condition

- Coolant and oil levels

- Refrigerant level

- Compressor and condenser performance

Electrical & Controls

- Battery health and connections

- Sensor and control calibrations

- Check for logged fault codes (don’t clear without investigation)

Doors, Seals & Insulation

- Inspect and replace worn door seals

- Ensure insulation is intact

Telematics & Software

- Update unit firmware

- Verify telematics data connectivity and alerts for remote monitoring

Preventing Breakdowns During Peak Produce Season

Temperature extremes of spring and summer put increased load on your refrigeration units.Good habits that reduce breakdowns include:

- Daily pre-trip inspections: automated pre-trip diagnostics take about 15 minutes and identify issues before loading.

- Set proper load temperature before trips to reduce workload later.

- Check condenser coils and airflow to avoid efficiency loss.

- Document maintenance and inspections: important for warranty and long-term performance.

Software Updates and Telematics System Checks

Modern reefers include telematics for real-time monitoring of temperatures, alarms, and performance metrics. Systems like Thermo King’s ConnectedSuite help you spot inefficiencies, alert on anomalies, and track long-term trends.

Perform software and firmware checks during your pre-season service. Updated systems improve predictive maintenance and can reduce unplanned service events.

Genuine Thermo King Parts vs Aftermarket

While aftermarket parts may seem cheaper upfront, Thermo King recommends using genuine replacement parts and certified dealer service for optimal uptime:

- Factory parts are designed for your specific model and backed by warranty when installed by certified dealers.

- Thermo King certified technicians use tools and processes that help ensure reliability.

Service Scheduling Across All 5 Thermo King Northeast Locations

Thermo King Northeast operates multiple fully-equipped service centers staffed by certified technicians. Services include:

- Preventative maintenance

- Warranty and PM plans

- 24/7 roadside or mobile assistance

- Diagnostics and upgrades

- Pre-season and winter inspection packages

Locations include facilities in Windsor Locks, CT; Falmouth, ME; Seekonk & Saugus, MA; and West Seneca, NY. Serving all of the Northeast.

Pre-season maintenance is a season-defining strategy. With proactive service, telematics in place, and genuine Thermo King parts installed by certified Thermo King technicians, you reduce breakdowns, protect cargo integrity, and extend the life of your refrigeration assets. Start your year right. Schedule your inspections now and stay ahead of the heat.